Cavity Wall Insulation Scotland

What Is Insulation

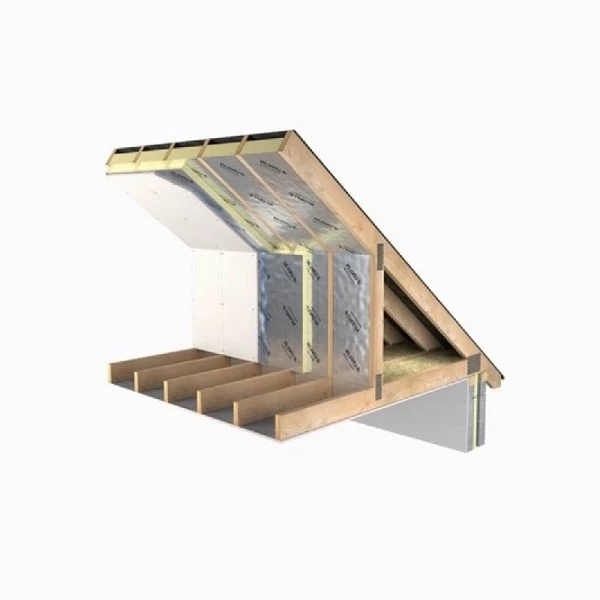

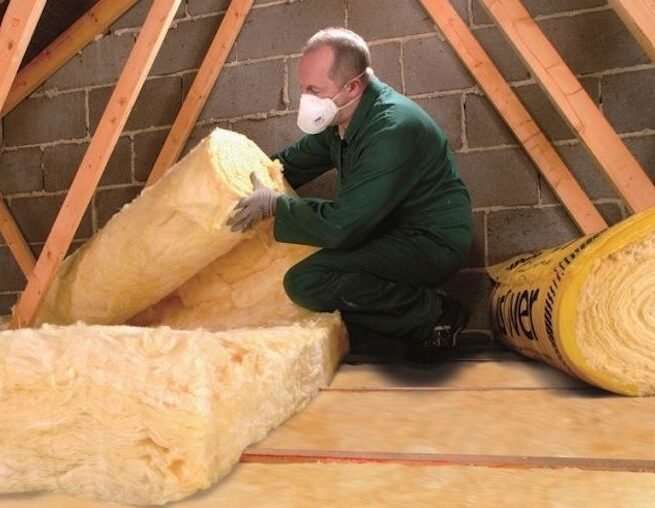

Insulation is a material you place as a barrier between your roof, wall and floor spaces. It is either placed between the rafters (the beams used to support the roof, the joists or the horizontal beams fitted along the floor of your attic.)

Insulation is done in order to slow down and prevent the heat transfer happening between the outside world and your living space. This creates a warmer environment inside the house during winter and a cooler environment during the summer.

What Is Cavity Wall Insulation?

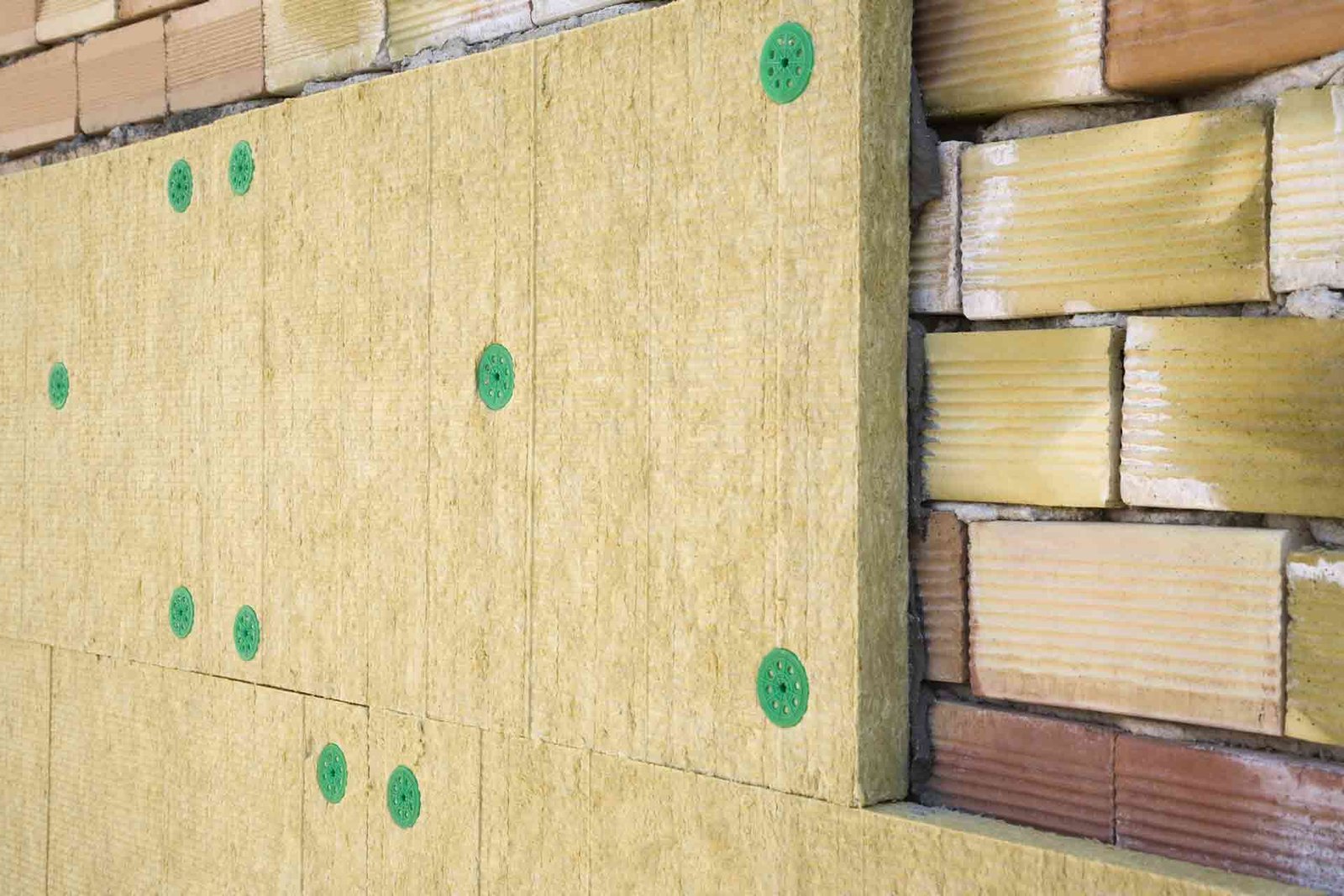

Cavity wall insulation is the method of insulating the space between the inner and outer walls of a building with outer cavity wall generally made of brick and inner wall comprising of concrete, structural clay or also brick, unlike solid stone walls where internal wall insulation is more suitable.

Cavity wall insulation is typically installed in homes with cavity walls, which feature two layers of brick or block separated by a gap, this insulation aims to minimise heat loss, enhance energy efficiency, and lower heating expenses.

- Your external walls should be unfilled cavity. Start with a borescope inspection, which is when you drill a tiny hole in your walls to confirm whether they are filled or hollow.

- Once you establish its cavity, confirm it is a minimum of 50mm wide and clear of any rubble.

According the Energy Savings Trust around 33% of heat is lost through cavity walls, if your homes walls are suitable it is one of the most effective types of home insulation you can install alongside loft insulation.

Professional installation is paramount, below are some of the things an installer should assess to determine if cavity wall insulation is best for your home:

- Your homes masonry and brickwork should be in good condition for effective cavity wall installation.

- If you have any damp currently, your walls should not be insulated until this is resolved.

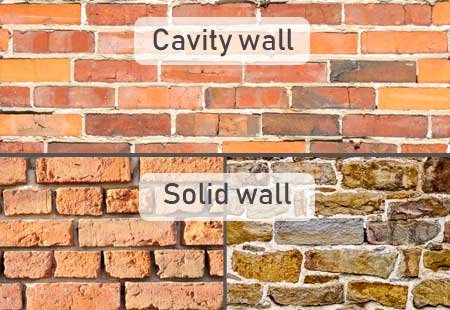

Shown are the different types of wall suitable for either cavity wall or internal wall insulation.

How does Cavity Wall Insulation Work?

Cavity wall insulation involves filling the gap between the inner and outer walls of a building with an insulating material to minimise heat loss and enhance energy efficiency.

Here’s an overview of how the process typically works:

Cavity Wall Construction

Cavity walls consist of two layers of brick or block separated by a gap or cavity. This gap allows for the installation of insulation while providing moisture protection.

Cavity Wall Insulation Material Selection

Common materials include mineral wool (such as glass wool or rock wool) or polystyrene beads known as cavity wall beads.

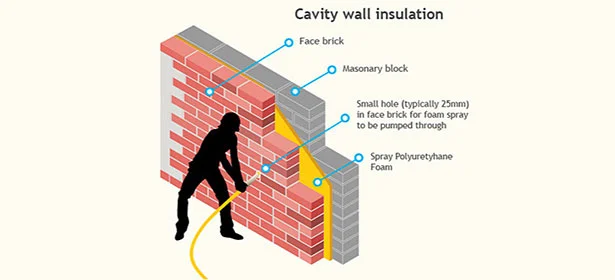

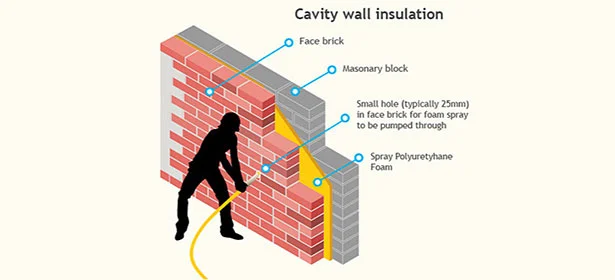

Drilling Holes

Small holes are drilled into the external wall at regular intervals to inject the insulation material.

Injection of Insulation Material

The selected material is injected into the cavity through the drilled holes, expanding or filling the space

Sealing of Holes

Once the cavity is filled, the drilled holes are sealed with colour matched mortar to maintain the exterior wall’s appearance.

Inspection and Quality Control

A professional may inspect the installation to ensure even coverage and absence of gaps or voids

Key Benefits

Thermal Barrier: Insulation reduces heat transfer through walls, improving interior comfort.

Energy Efficiency: Cavity wall insulation reduces the need for heating or cooling, leading to potential energy savings.

Condensation Control: Helps prevent dampness and mould by controlling interior moisture levels.

It’s essential to assess a building’s suitability for cavity wall insulation and ensure compliance with building regulations and standards during material selection and installation.

Shown are the different types of wall suitable for either cavity wall or internal wall insulation.

Benefits Of Cavity Wall Insulation

Cavity wall insulation offers several benefits for homeowners, contributing to increased energy efficiency, improved comfort, and potential cost savings.

Here are some key advantages of cavity wall insulation:

Reduced Heat Loss

Cavity wall insulation acts as a thermal barrier, reducing the transfer of heat through the walls. This helps to retain warmth in the winter, leading to a more energy-efficient home

Lower Energy Bills

By reducing heat loss, cavity wall insulation can result in lower heating bills. A well-insulated home requires less energy to maintain a comfortable temperature.

Consistent Indoor Temperatures

Insulated walls help maintain more stable indoor temperatures. This means warmer interiors in the winter and cooler interiors in the summer.

Minimal Disruption Installation

Cavity wall insulation is often a quick and straightforward installation process that can be completed in a day. This minimises disruption to occupants.

Lower Carbon Emissions

A more energy efficient home results in lower carbon emissions. By reducing the need for heating, cavity wall insulation contributes to environmental sustainability.

Increased Property Value

Improving the energy performance of a property through insulation measures can enhance its market value. Many homebuyers appreciate energy efficient features.

Government Grants

In Scotland Government grants are available to encourage homeowners to install cavity wall insulation. These financial incentives will offset your installation costs.

Durability

Cavity wall insulation, when installed correctly, can be a long-lasting solution. It requires minimal maintenance and continues to provide benefits over the long term.

Reduction in Noise

In addition to thermal benefits, cavity wall insulation can contribute to sound insulation. It helps reduce the transmission of external noise into the home, creating a quieter living environment.

How does Cavity Wall Insulation Work?

Cavity wall insulation involves filling the gap between the inner and outer walls of a building with an insulating material to minimise heat loss and enhance energy efficiency.

Here’s an overview of how the process typically works:

Cavity Wall Construction

Cavity walls consist of two layers of brick or block separated by a gap or cavity. This gap allows for the installation of insulation while providing moisture protection.

Cavity Wall Insulation Material Selection

Common materials include mineral wool (such as glass wool or rock wool) or polystyrene beads known as cavity wall beads.

Drilling Holes

Small holes are drilled into the external wall at regular intervals to inject the insulation material.

Injection of Insulation Material

The selected material is injected into the cavity through the drilled holes, expanding or filling the space

Sealing of Holes

Once the cavity is filled, the drilled holes are sealed with colour matched mortar to maintain the exterior wall’s appearance.

Inspection and Quality Control

A professional may inspect the installation to ensure even coverage and absence of gaps or voids

Key Benefits

Thermal Barrier: Insulation reduces heat transfer through walls, improving interior comfort.

Energy Efficiency: Cavity wall insulation reduces the need for heating or cooling, leading to potential energy savings.

Condensation Control: Helps prevent dampness and mould by controlling interior moisture levels.

It’s essential to assess a building’s suitability for cavity wall insulation and ensure compliance with building regulations and standards during material selection and installation.

Shown are the different types of wall suitable for either cavity wall or internal wall insulation.

Best Material For Cavity Wall Insulation

The selection of cavity wall insulation material hinges on diverse factors, encompassing building specifications, climate, and individual preferences.`

Here are some prevalent types of cavity wall insulation materials:

Mineral Wool (Glass Wool or Rock Wool)

Benefits:

Exhibits commendable thermal insulation properties.

Non-combustible and endowed with fire-resistant attributes.

Shows resilience against moisture absorption.

Offers potential for sound insulation.

Considerations:

Mandates professional installation to ensure uniform coverage.

Foam Insulation (Polyurethane or Polystyrene):

Benefits:

Boasts high thermal insulation capabilities.

Lightweight and facilitates easy installation.

Demonstrates resistance to moisture.

Renders a seamless and airtight seal.

Considerations:

Certain foams may emit gases during installation, necessitating proper ventilation.

Initial cost might be higher.

Cellulose Insulation

Benefits:

Crafted from recycled paper, rendering it environmentally friendly.

Effective thermal insulation performance.

Can be injected into the cavity.

Considerations:

May necessitate additives to enhance fire resistance.

Moisture resistance levels can vary.

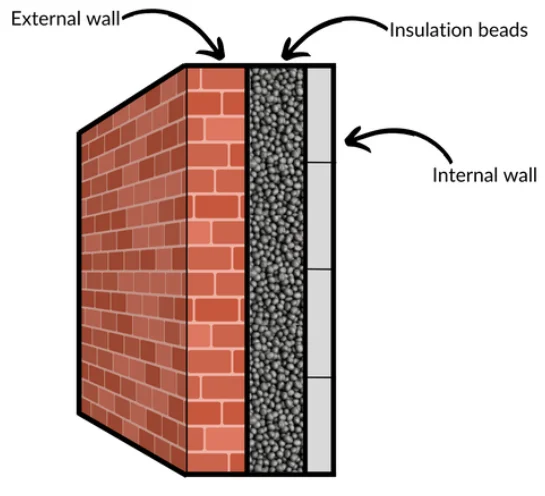

Cavity Bead Insulation (Expanded Polystyrene Beads)

Benefits:

Crafted from recycled paper, rendering it environmentally friendly.

Effective thermal insulation performance.

Can be injected into the cavity.

Considerations:

May necessitate additives to enhance fire resistance.

Moisture resistance levels can vary.

Cavity Bead Insulation (Expanded Polystyrene Beads)

Benefits:

Lightweight and facilitates straightforward installation.

Possesses commendable thermal insulation properties.

Shows resistance to moisture.

Considerations:

Requires professional installation.

May experience settling over time, potentially affecting performance.

Cavity insulation beads are generally the best type of material to install.

Diagram shown external and internal walls with the cavity wall insulation beads installed in-between

Problems Due To Poor Installation

There has been some news articles in Scotland documenting problems with cavity wall insulation due to poor installation, issues including reports of dampness and moisture. We can assure you that our partner installers will ensure your installation is done correctly with thousands of successful jobs being completed over the years. There are a lot of steps to follow when installing cavity wall insulation, so it’s important to have installers well versed in fitting it who will understand and avoid any of the issues below arising.

Some issues are caused by thermal bridging which occurs when there is a break in the insulation layer, allowing a direct pathway for heat to bypass the insulating material.

Potential Consequences of Thermal Bridging

Reduced Energy Efficiency:

Thermal bridging can compromise the overall energy efficiency of the building, leading to increased heat loss and higher energy bills.

Cold Spots and Condensation:

Areas with thermal bridging may become cold spots on the internal walls, potentially leading to issues like condensation and dampness.

This can impact occupant comfort and indoor air quality.

Mould Growth:

Cold spots and condensation can create conditions favourable for mould growth, posing health risks and requiring additional remediation measures.

There are other issues with installing cavity wall insulation on listed buildings, it can be a complex issue, and there are specific considerations and regulations that must be followed due to the historic and protected nature of these premises. Listed buildings are those officially recognised and protected for their special architectural or historic interest.

If you are put off cavity wall insulation, you can consider other options such as internal wall insulation and loft insulation

Damp and aged cavity wall insulation removal

Cavity Wall Insulation Removal and Replacement

If you have had an installation completed that has had some of issues highlight above, you can have cavity wall insulation removal and replacement carried out to solve the problem. This is also referred to as cavity wall extraction and refill.

Sometimes people have cavity wall removed and replaced not because of any of the highlighted issues or any major problems, simply due to it being aged.

If your cavity wall was insulated around 15 to 20 years ago, it will have older less effective materials that are not as efficient as what is available today.

Here’s more information about the extraction and refill process:

The Extraction Process

Reduced Energy Efficiency:

Thermal bridging can compromise the overall energy efficiency of the building, leading to increased heat loss and higher energy bills.

Cold Spots and Condensation:

Areas with thermal bridging may become cold spots on the internal walls, potentially leading to issues like condensation and dampness.

This can impact occupant comfort and indoor air quality.

Mould Growth:

Cold spots and condensation can create conditions favourable for mould growth, posing health risks and requiring additional remediation measures.

There are other issues with installing cavity wall insulation on listed buildings, it can be a complex issue, and there are specific considerations and regulations that must be followed due to the historic and protected nature of these premises. Listed buildings are those officially recognised and protected for their special architectural or historic interest.

The Refill Process

Selection of Insulation Material:

Based on factors such as building requirements, climate, and energy efficiency goals, a suitable insulation material is chosen for the refill. Common options include mineral wool, foam insulation, or cellulose insulation.

New Installation:

The new selected insulation material is injected or blown into the wall cavities using specialised equipment. Care is taken to ensure that the cavities are completely filled and that the insulation forms a continuous barrier.

Quality Assurance:

After the refill process is complete, a thorough inspection is conducted to verify that the insulation has been installed correctly and that the cavities are properly filled.

Benefits of Extraction and Refill

Improved Energy Efficiency:

New insulation materials can enhance the thermal performance of the building, reducing heat loss and energy consumption by up to 33 percent.

Enhanced Comfort:

Properly insulated walls help maintain more consistent indoor temperatures and reduce drafts, resulting in increased comfort for occupants.

Moisture Management:

Upgrading insulation can help mitigate moisture problems and improve the overall indoor air quality.

Long Term Savings:

Investing in efficient insulation can lead to lower energy bills and potentially increase the value of the property.

Cavity wall insulation removal and replacement can be a cost effective as in most cases you will qualify for a government grant and it is one of the most efficient ways to upgrade the thermal performance of your building, leading to improved comfort, energy savings, and environmental sustainability.

Professional cavity wall insulation removal and replacement

History Of Cavity Wall Insulation in Scotland

(Early Developments)

The history of cavity wall insulation in Scotland reflects broader trends in building practices and energy efficiency awareness. Here’s a detailed overview:

Mid-20th Century

1970s-1980s

1990s

2000s

2010s to Present

Current Trends in 2024

Cavity Wall Insulation Installers Scotland

As stated our insulation installers partners are well versed in installing cavity wall insulation, they have thousands of installs completed successfully and will ensure your project is completed following the same process.

We can also discuss and provide the best alternative options for your home or if cavity wall insulation is not suitable.

All of the installers we work with are fully approved with the likes of TrustMark meaning they are able to install insulation where funding is awarded via government grant schemes.

Cavity wall insulation and loft insulation are the most prevalent forms of home insulation in Scotland in terms of demand, hence it is heavily supported by government grants to cover the installation cost. As well as grants for cavity wall insulation, customers frequently seek grants for loft insulation, funding is awarded in relation to eligibility and what will enhance your home’s EPC rating more.

There are various insulation grants available including popular Home Energy Scotland grant and loan scheme, the ECO 4 scheme and the Great British Insulation scheme.

Insulation Scotland’s partners are on hand to aid you in your application process and will also subsequently install your cavity wall insulation if you secure funding.

For additional details and to discuss if you qualify for a grant, please call us or complete our short contact form.

For additional details and to discuss if you qualify for a grant, please call us or complete our short contact form.

ECO Flex Cavity Wall Insulation Grant

The ECO flex or local authority flex stands as an additional grant option for cavity wall insulation. This particular grant is limited to the North Lanarkshire, South Lanarkshire, and Renfrewshire council areas, where our endorsed partners serve as approved installers.

ECO flex extends financial support to individuals not receiving benefits but earning less than £31,000. Eligibility criteria include having a home EPC rating below D and meeting other specified conditions.

For more information on all of the government grants available for home insulation, visit our Insulation Grants Scotland page.

Facts On Scotland

We have partner installers all over Scotland, here are some interesting facts about our great nation:

Population: Official statistics project that Scotland’s population will increase from 5.35 million in 2014 to 5.51 million by 2024, and further to 5.7 million by 2039.

Biggest Cities: According to Wikipedia the biggest cities in Scotland by population are Glasgow – 632,350. Edinburgh – 506,520 and Aberdeen – 198,590.

There are many famous Scots, some of the most notable include Alexander Graham Bell, John Logie Baird, Mary, Queen of Scots and William Wallace.

Scotland, and in particular Glasgow played a huge role in the Industrial Revolution, the city diversified into heavy industries like shipbuilding, locomotive construction and other heavy engineering that could thrive on nearby supplies of coal and iron ore. Between 1870 and 1914, Glasgow ranked was one of the richest and finest cities in Europe.

The famous Edinburgh festival is the largest arts festival in the world showcasing up and coming acts for arts, drama, live music and especially comedy, having helped many successful artists launch their careers.

Get In Touch With Us

What Sets Us Apart

Approved Insulation Contractors

ScotTherm only works with experienced and approved insulation contractors who have a proven track record across the country. They have all of the required accreditations and a strong reputation in the industry. Our aim, along with our partners is to properly insulate homes in via underfloor, internal, external and cavity wall insulation, loft and roof insulation.

Best Eco-Friendly Materials

Mineral wool insulation is a type of material made from natural or synthetic minerals. It is commonly used to insulate residential and commercial buildings, and is an eco-friendly solution. We offer various sustainable insulation materials which include Knauf mineral wool which is the UK’s leading brand, specifically their Earthwool and Rockwool products.

For sheeps wool material, ThermaFleece Cosywool is used.

Foil & Insulation Boards

Foil insulation and PIR rigid insulation boards are perfect for room in roof insulation, some loft and roof insulation providing another option. Our goal is to provide you with the best insulation type for your home, rather than just insist one material is best for all circumstances!

Grants Available

ScotTherm and the installers we work with are TrustMark approved, meaning they can install insulation after funding has been awarded via various schemes such as the governments ECO 4 scheme, the Great British Insulation Scheme and the Warmer Homes Scotland grant from Home Energy Scotland.

Satisfaction Guaranteed

Our own installation team and our partner installers have a set protocol they follow on every job to ensure we maintain the highest standards possible. This includes a thorough inspection at the end of every job completed by one of their senior members of staff.

Knauf Mineral Wool And Earthwool

Optimum thermal performance.

Slows heat transfer.

Eco-friendly, sustainable product.

Sound insulation benefits.

Creates dry, comfortable conditions.

Fire protection.

(PIR) Rigid Insulation Boards

Thin, light, durable.

Reduced humidity.

Hassle free installation.

No maintenance requirements.

Ideal for certain angles.

Clean and tidy.

ThermaFleece Sheeps Wool Insulation

Over 20 years of research and development.

Best heat retention insulation.

Natural, sustainable product.

Comes from British farms.

Acoustic benefits.

INSULATION SERVICES WE OFFER

ScotTherm either directly installs or can provide quotes via our partner installers for every type of insulation measure there is.

We strictly don’t use spray foam insulation on domestic properties.

Loft Insulation

Read more on about the loft insulation and government grants available in Scotland.

External Wall Insulation (ewi)

Click the link above for more information on our external wall insulation services.

Internal Wall Insulation

Internal wall insulation with government grants also available.

Cavity Wall Insulation

Click the link above for more information on cavity wall insulation and the government grants available for it.

Underfloor Insulation

Read more on our underfloor and suspended floor insulation solutions.

Roof Insulation

Click the link above for more information on our roof and loft insulation services.

INSULATION SERVICES WE OFFER

ScotTherm either directly installs or can provide quotes via our partner installers for every type of insulation measure there is.

We strictly don’t use spray foam insulation on domestic properties.